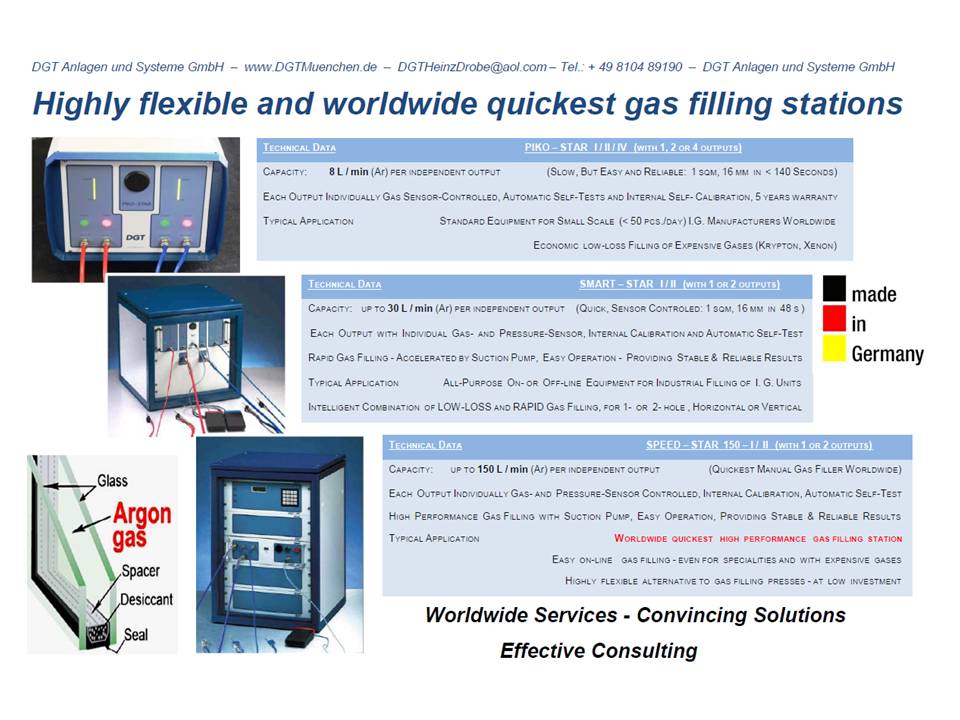

SMART-STAR 100 – I / II

High Performance Gas Filler with Multi-Sensor Control

Multisensor-controlled rapid gas filling station designed to improve thermal and acoustic properties of insulating glass units by low-loss high performance gas filling with premixed, technical or noble gases (e.g. Argon, SF6, Krypton or Xenon) for I.G. manufacture on industrial scale with up to 750 units per shift, depending on pane dimensions

Function & Design

| Technical Data |

SMART-STAR 100 – I / II |

|---|---|

| Number of independent outputs | 1 or 2 further outputs on requested |

| Flow Rate capacity per output | 30 L / min. (Ar) |

| Overall output capacity | 30 resp. 60L / min. (Ar) |

| Height x width x depth, weight | 630mm x 600mm x 600mm, 50kg |

| Power supply | 110V/230V ± 10%, 50Hz/60Hz (as requested) |

| Power input / Stand-by | max. 350VA / 100 VA |

| Additional customized options | on request |

Technical changes reserved.

| Technical Data – SMART-STAR |

|---|

| Number of independent outputs 1 or 2 further outputs on requested |

| Flow Rate capacity per output 30 L / min. (Ar) |

| Overall output capacity 30 resp. 60L / min. (Ar) |

| Height x width x depth, weight 630mm x 600mm x 600mm, 50kg |

| Power supply 110V/230V ± 10%, 50Hz/60Hz (as requested) |

| Power input / Stand-by max. 350VA / 100 VA |

| Additional customized options on request |

Technical changes reserved.

Typical Applications