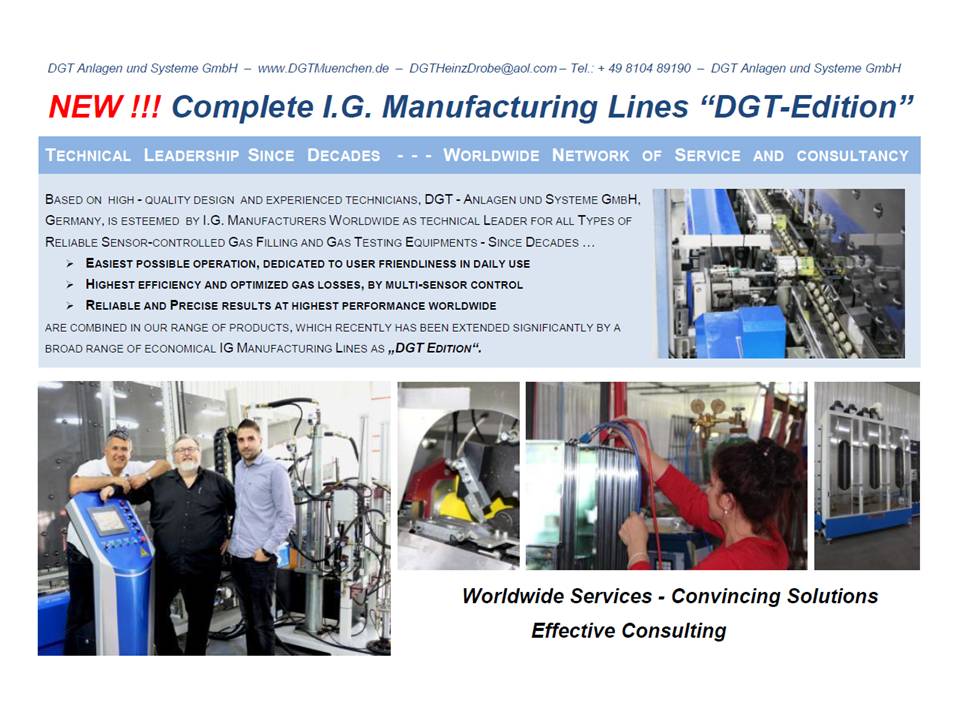

Worldwide Services, Convincing Solutions, Effective Consulting

DGT – Anlagen und Systeme GmbH . . .

. . . your center of expertise for reliable gas filling equipment and mobile gas analyzers

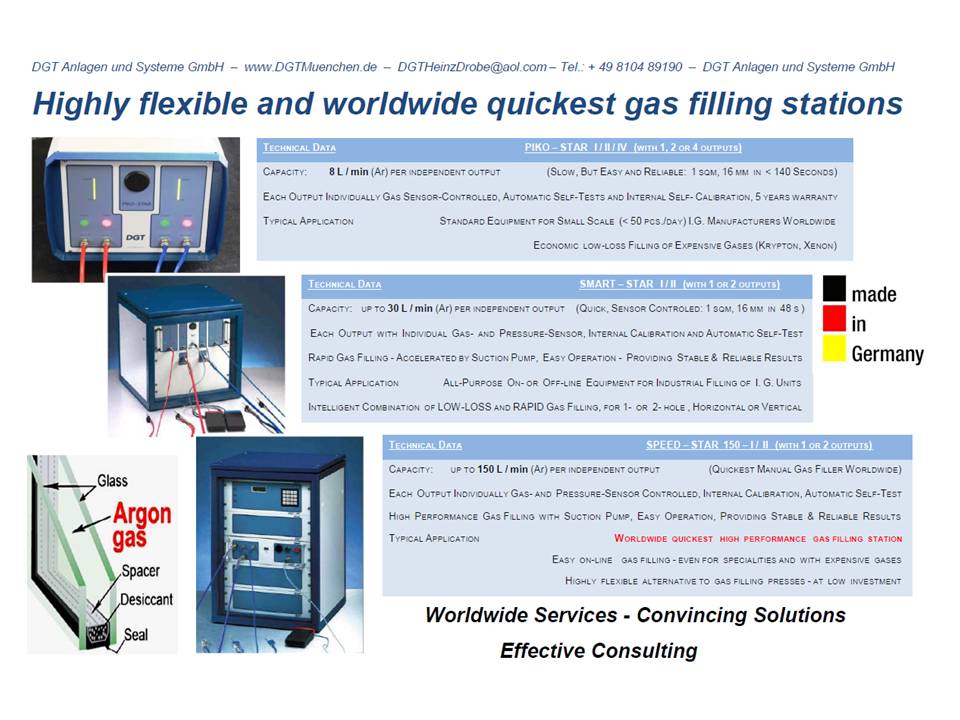

PIKO-STAR:

All-purpose gasfilling station with sensor-control and integrated mixing units for reliable off-line ultralow-loss gasfilling operation even for specialities, designed for I.G. manufacture on a medium scale with up to 250 units per shift (2 outputs) resp. up to 400 units per shift (4 outputs).

SMART-STAR:

Multisensor-controlled rapid gasfilling station with integrated mixing units for flexible, high performance gasfilling operation even for specialities, designed for I.G. manufacture on an industrial scale with up to 750 units per shift

SPEED-STAR:

High performance multi-sensor controlled rapid gas filling station with integrated suction units, automatic size recognition procedures, self-adjusting flow rates and on-line mbar pressure sensing for suction and flow control for I.G. manufacture on industrial scale with typically 1200, but up to 1800 units per shift (depending on pane dimensions), with worldwide highest total filling rates of up to 300 l/min and cycle times around 30 s

Additionally, many taylorized solutions had been designed and fabricated for special applications, on request.

Please do not hesitate to contact us for all related questions.

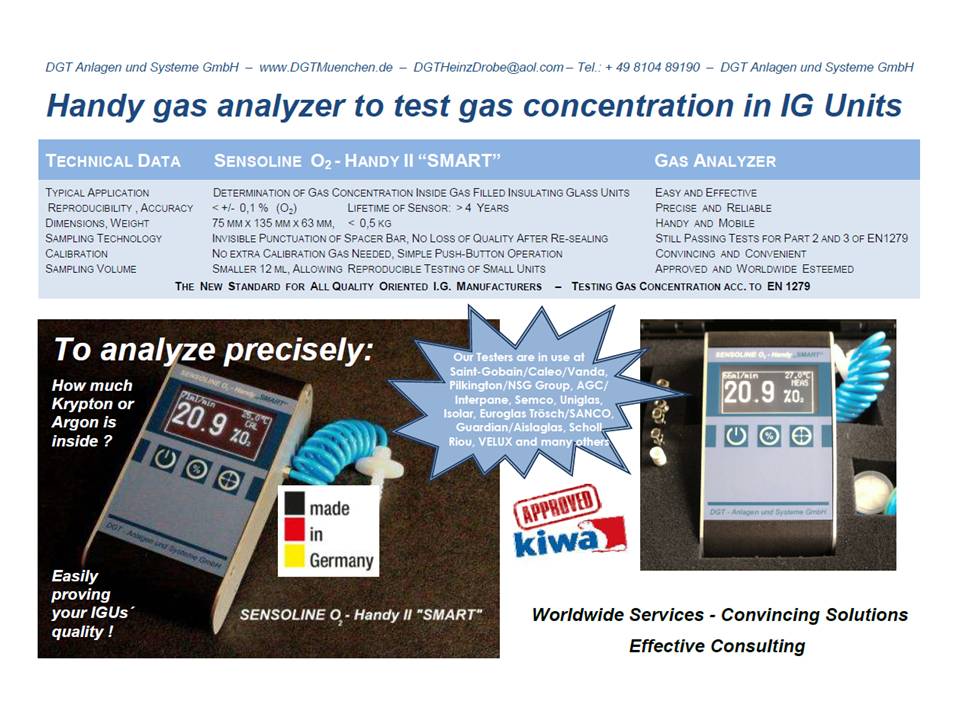

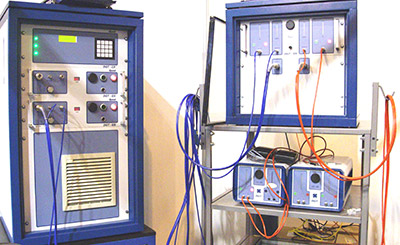

SENSOLINE:

Economic and precise measurement and testing equipment to easily determine gas filling concentration of sealed I.G. units

The most comprehensive range of I.G. – gasfilling equipment worldwide:

The most comprehensive range of I.G. – gasfilling equipment worldwide:

| Dimension of IG units – PIKO-STAR |

|---|

| 1100x800x12 91,00 |

| 1000x1000x16 150,00 |

| 1200x2500x12 380,00 |

| 1630x2500x12 500,00 |

| 1630x2500x16 700,00 |

| Dimension of IG units – SMART-STAR |

|---|

| 1100x800x12 30,00 |

| 1000x1000x16 49,00 |

| 1200x2500x12 80,00 |

| 1630x2500x12 105,00 |

| 1630x2500x16 140,00 |

| Dimension of IG units – SPEED-STAR |

|---|

| 1100x800x12 29,00 |

| 1000x1000x16 30,00 |

| 1200x2500x12 40,00 |

| 1630x2500x12 45,00 |

| 1630x2500x16 58,00 |

| Dimension of IG units | PIKO-STAR | SMART-STAR | SPEED-STAR |

|---|---|---|---|

| 1100x800x12 | 91,00 | 30,00 | 29,00 |

| 1000x1000x16 | 150,00 | 49,00 | 30,00 |

| 1200x2500x12 | 380,00 | 80,00 | 40,00 |

| 1630x2500x12 | 500,00 | 105,00 | 45,00 |

| 1630x2500x16 | 700,00 | 140,00 | 58,00 |

Dependable

—-Gas filling

——–Technology

…keeping gas filling easy

…just gas filling

SPEED-STAR

Economic and precise measurement and testing equipment to easily determine gas filling concentration of sealed I.G. units